Ipleyiti yeSimbi yoLwakhiwo lweMozulu yoMvelisi waseTshayina yokuhonjiswa kweSakhiwo

(1)Intsimbi yemozulu ephezulu

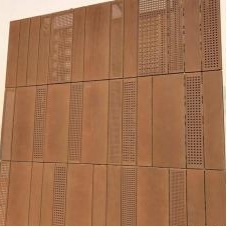

Ukumelana nemozulu ephezulu yentsimbi yesakhiwo kukongeza inani elincinci lobhedu, i-phosphorus, i-chromium, kunye ne-nickel kwintsimbi ukwenza umaleko okhuselayo kumphezulu we-collective yesinyithi ukuphucula ukusebenza kwentsimbi ngokuchasene ne-corrosion ye-atmospheric.Ungongeza kwakhona inani elincinci le-molybdenum, i-niobium, i-Elements ezifana ne-vanadium, i-titanium kunye ne-zirconium inokucoca iinkozo, iphucule iimpawu zentsimbi, iphucule amandla kunye nokuqina kwentsimbi, ukunciphisa ubushushu benguqu enqabileyo, kwaye iyenze ibe nayo. ukuxhathisa okungcono kwi-brittle fracture.

(2)Intsimbi yemozulu yesakhiwo esidityanisiweyo

Izinto ezongeziweyo kwintsimbi, ngaphandle kwe-phosphorus, zifana ngokusisiseko nokumelana nemozulu ephezulu yentsimbi yesakhiwo, kwaye inomsebenzi ofanayo nayo, kwaye iphucula ukusebenza kwe-welding.

Ukusetyenziswa kwentsimbi yolwakhiwo oluphezulu lwemozulu lungcono kunentsimbi yokumelana nemozulu kwisakhiwo esidityanisiweyo ngenxa yokumelana ne-atmospheric corrosion.Isetyenziselwa ikakhulu ukwenza iibholiti, iiriveting kunye nokuwelda iinxalenye zezakhiwo zezithuthi, izikhongozeli, izakhiwo, iinqaba kunye nezinye izakhiwo.Xa isetyenziswe njengeendawo ezidityanisiweyo zesakhiwo, ubukhulu bentsimbi akufanele bube bukhulu kune-16mm.Intsimbi ekwaziyo ukumelana nemozulu kwizakhiwo ezidityanisiweyo inomsebenzi ongcono wokuwelda kunentsimbi yolwakhiwo olunokumelana nemozulu ephezulu, kwaye isetyenziswa ikakhulu kwizakhiwo ezidityanisiweyo kwiibhulorho, izakhiwo kunye nezinye izakhiwo.

Qaphela: sibonelela ngenkonzo yokwenza ngokwezifiso, yonke ityhubhu yentsimbi iya kuxhomekeka kuyilo lwakho ukuyivelisa.

| Inqanaba lokumelana nemozulu kunye nesalathiso sokusebenza | ||||||||||||||

| IBanga leNsimbi | Umgangatho | Amandla eSivuno N/mm2 | Amandla Okuqina N/mm2 | Elongation % | ||||||||||

| Corten A | I-ASTM | ≥345 | ≥480 | ≥22 | ||||||||||

| UCorten B | ≥345 | ≥480 | ≥22 | |||||||||||

| A588 G.A | ≥345 | ≥485 | ≥21 | |||||||||||

| A588 GR.B | ≥345 | ≥485 | ≥21 | |||||||||||

| A242 | ≥345 | ≥480 | ≥21 | |||||||||||

| S355J0W | EN | ≥355 | 490-630 | ≥27 | ||||||||||

| S355J0WP | ≥355 | 490-630 | ≥27 | |||||||||||

| S355J2W | ≥355 | 490-630 | ≥27 | |||||||||||

| S355J2WP | ≥355 | 490-630 | ≥27 | |||||||||||

| I-SPA-H | I-JIS | ≥355 | ≥490 | ≥21 | ||||||||||

| I-SPA-C | ≥355 | ≥490 | ≥21 | |||||||||||

| SMA400AW | ≥355 | ≥490 | ≥21 | |||||||||||

| 09CuPCrNi-A | GB | ≥345 | 490-630 | ≥22 | ||||||||||

| I-B480GNQR | ≥355 | ≥490 | ≥21 | |||||||||||

| Q355NH | ≥355 | ≥490 | ≥21 | |||||||||||

| Q355GNH | ≥355 | ≥490 | ≥21 | |||||||||||

| Q460NH | ≥355 | ≥490 | ≥21 | |||||||||||

| Corten | C% | Si% | Mn% | P% | S% | Ni% | Cr% | Cu% | ||||||

| ≤0.12 | 0.30-0.75 | 0.20-0.50 | 0.07-0.15 | ≤0.030 | ≤0.65 | 0.50-1.25 | 0.25-0.55 | |||||||

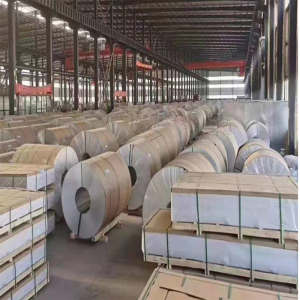

| Ubungakanani | ||||||||||||||

| Ukutyeba | 0.3mm-2mm(kubanda kuqengqeleka) | |||||||||||||

| Ububanzi | 2mm-50mm(hot rolled) | |||||||||||||

| Ubude | Ikhoyili okanye njengoko ufuna ubude | |||||||||||||

| Eqhelekileyoubukhulu | Ikhoyili:4/6/8/12*1500/1250/1800*Ubude(obulungiselelweyo) | |||||||||||||

| Icwecwe:16/18/20/40*2200*10000/12000 | ||||||||||||||