China Intengiso eshushu NM360.NM400.NM450 NM500 NM500 Nxiba ipleyiti yentsimbi enganyangekiyo

Ipleyiti yensimbi engaguqukiyo ihlanganiswe nentsimbi ephantsi yekhabhoni kunye ne-alloy wear-resistant layer.Umaleko we-alloy onganyangekiyo ngokuqhelekileyo yi-1/3 ukuya kwi-1/2 yobukhulu obupheleleyo.Xa usebenza, i-matrix ibonelela ngeempawu ezibanzi njengamandla, ukuqina kunye neplastiki ngokuchasene nemikhosi yangaphandle, kunye ne-alloy wear-resistant layer ibonelela ngokumelana nokunxiba okuhlangabezana neemfuno zeemeko zokusebenza ezichaziweyo.

Kukho i-metallurgical bond phakathi kwentsimbi enganyangekiyo kwipleyiti yealloyi yokunxiba umaleko kunye ne-substrate.Ngezixhobo ezikhethekileyo kunye nenkqubo ye-welding ngokuzenzekelayo, i-high-hardness self-shielding i-alloy welding wire idityaniswe ngokufanayo kwi-substrate.Umaleko odityanisiweyo unomaleko omnye ukuya kubini okanye nakumaleko amaninzi.Ngethuba lenkqubo edibeneyo, ngenxa ye-shrinkage ratio ye-alloy, ukuqhekeka kwe-uniform transverse kubonakala.Yinto ephawulekayo kwipleyiti yentsimbi engagungqiyo.

1. Umatshini wamandla obushushu obushushu: i-cylinder lining ye-medium-speed coal mill, iqokobhe le-fan impeller, i-inlet flue yomqokeleli wothuli, umbhobho wothuthu, umgca we-injini ye-emele, umbhobho wokudibanisa wesahluli, Icwecwe lesityumli samalahle Ipleyiti, iliner yehopper yamalahle kunye nesityumli, isitshisi sesitshisi, iliner yehopper yamalahle kunye nefunnel, inkxaso yethayile yesifudumezi somoya, ivane yesikhokelo sesahluli.Intsimbi esetyenziswe koomatshini abangasentla inokucutshungulwa zonke iipleyiti zetsimbi ezingagugiyo.

2. Iyadi yamalahle: ucweyo lwendawo yokuxheshisela kunye nehopper, ucweyo lwehopper, iincakuba zefeni, ipleyiti esezantsi yepusher, iliner yokuqokelela uthuli lwenkanyamba, isikhokelo secoke, umgca webhola. i-mill, i-drill stabilizer, i-spiral Intsimbi yesondlo kunye nesiseko sayo, umgca wangaphakathi we-emele ye-kneader, i-ring feeder, kunye nepleyiti esezantsi yelori yokulahla.Ngenxa yokuba ipleyiti kufuneka isetyenziswe kwiyadi yamalahle, kukho iimfuno ezithile zokumelana nokugqwala kunye nokumelana nokunxiba kwepleyiti yensimbi.Ngaphezu koko, indawo yokusetyenziswa kweyadi yamalahle inzima ngakumbi, kwaye olu hlobo lwezinto kufuneka lusetyenziswe ngcono.Ukusetyenzwa kwepleyiti yentsimbi ekwaziyo ukunxiba, efana ne-EH yochungechunge lwentsimbi engagungqiyo yaseJapan JFE kunye ne-DILLIDUR ipleyiti yentsimbi ekwaziyo ukunxiba yaseDillingen, eJamani.

3. Iplanti yesamente: i-chute lining, i-end bushing, umqokeleli wothuli lwenkanyamba, iibhleyidi zokwahlula umgubo kunye neencakuba zesikhokelo, iiblayidi zefeni kunye ne-lining, i-bucket lining, i-screw conveyor ezantsi ipleyiti, iinxalenye zemibhobho, i-frit cooling plate Lining, ibhodi yokuhambisa umkhombe.Ezi nxalenye nazo zifuna iipleyiti zetsimbi ezigugileyo kunye nokumelana nokuguga okungcono kunye nokuxhathisa ukubola, okudinga ipleyiti yensimbi engaguqukiyo ephathwa ngenkqubo ekhethekileyo.

4. Ukulayisha oomatshini: ukothula ipleyiti yokusila, ipleyiti ye-hopper lining, ipleyiti yokubamba i-blade, ibhodi yokulahla ilori ezenzekelayo, umzimba welori yokulahla.Oku kufuna iipleyiti zentsimbi ezinganxibiyo ezinokumelana nokunxiba okuphezulu kakhulu kunye nokuqina.Kunconywa ukusebenzisa i-JFE-EH-C500, i-JFE-EH-C550, i-DILLIDUR 500V, i-DILLIDUR 550V kunye nezinye izinto, kunye nobukhulu beplate yensimbi engaguqukiyo yi-25-45MM.

Oomatshini bokumbiwa kwemigodi: ii-linings, iiblades, ii-conveyor linings kunye nee-baffles zemathiriyeli yamaminerali kunye nezityuli zamatye.Amalungu anjalo afuna ukuxhathisa okuphezulu kakhulu kwaye anokucutshungulwa kunye neepleyiti zetsimbi ezinobunzima obuyi-10-30mm, njenge-JFE-EH-C500, JFE-EH-C550, DILLIDUR 500V, DILLIDUR 550V kunye nezinye izinto.

6. Oomatshini bokwakha: ipleyiti ye-cement pusher tooth, inqaba yokuxuba ikhonkrithi, i-mixer lining plate, ipleyiti yokuqokelela uthuli, ipleyiti yokubumba umatshini wezitena.Ngenxa yokuba iinxalenye zayo zilula ukunxiba, kucetyiswa ukuba kusetyenziswe iipleyiti zetsimbi ezingagungqiyo ezenziwe nge-JFE-EH-C340, JFE-EH-C400, DILLIDUR 400V kunye nezinye izinto ezinobunzima be-10-30mm.

7. Oomatshini bokwakha: ii-loaders, ii-bulldozers, iipleyiti zebhakethi ze-excavator, iipleyiti ze-side blade, iipleyiti ezisezantsi zebhakethi, ii-blades, i-rotary drilling rig drill rods.Olu hlobo lomatshini lufuna iipleyiti zentsimbi ezinxitywayo eziqinileyo kwaye ziyakwazi ukunxiba, kwaye zingenziwa nge-JFE-EH-C500, JFE-EH-C550, DILLIDUR 500V, DILLIDUR 550V kunye nezinye izinto, ezinobunzima obungama-20. -60mm.Ukucoca ipleyiti yentsimbi.

8. Umatshini we-Metallurgical: umatshini wokuhlamba intsimbi, i-elbow yokuhambisa, i-iron ore sintering machine liner, i-scraper liner.Ngenxa yokuba olu hlobo lomatshini alufuni kuphela ukuxhathisa ubushushu obuphezulu, kodwa lukwafuna ukusetyenziswa kweplate yentsimbi enzima kakhulu.

9. Ukusetyenziswa kweshishini kwiiplati zetsimbi ezigugileyo zihlala zibandakanya amashishini asibhozo angentla, kodwa kukho amashishini amaninzi asebenzisa iipleyiti zetsimbi ezinqabileyo.Iipleyiti zentsimbi ezikwaziyo ukunxiba zingasetyenziswa kumacandelo, zithwele iinxalenye zesakhiwo, iinxalenye zesakhiwo samavili kaloliwe, imiqulu, njl.

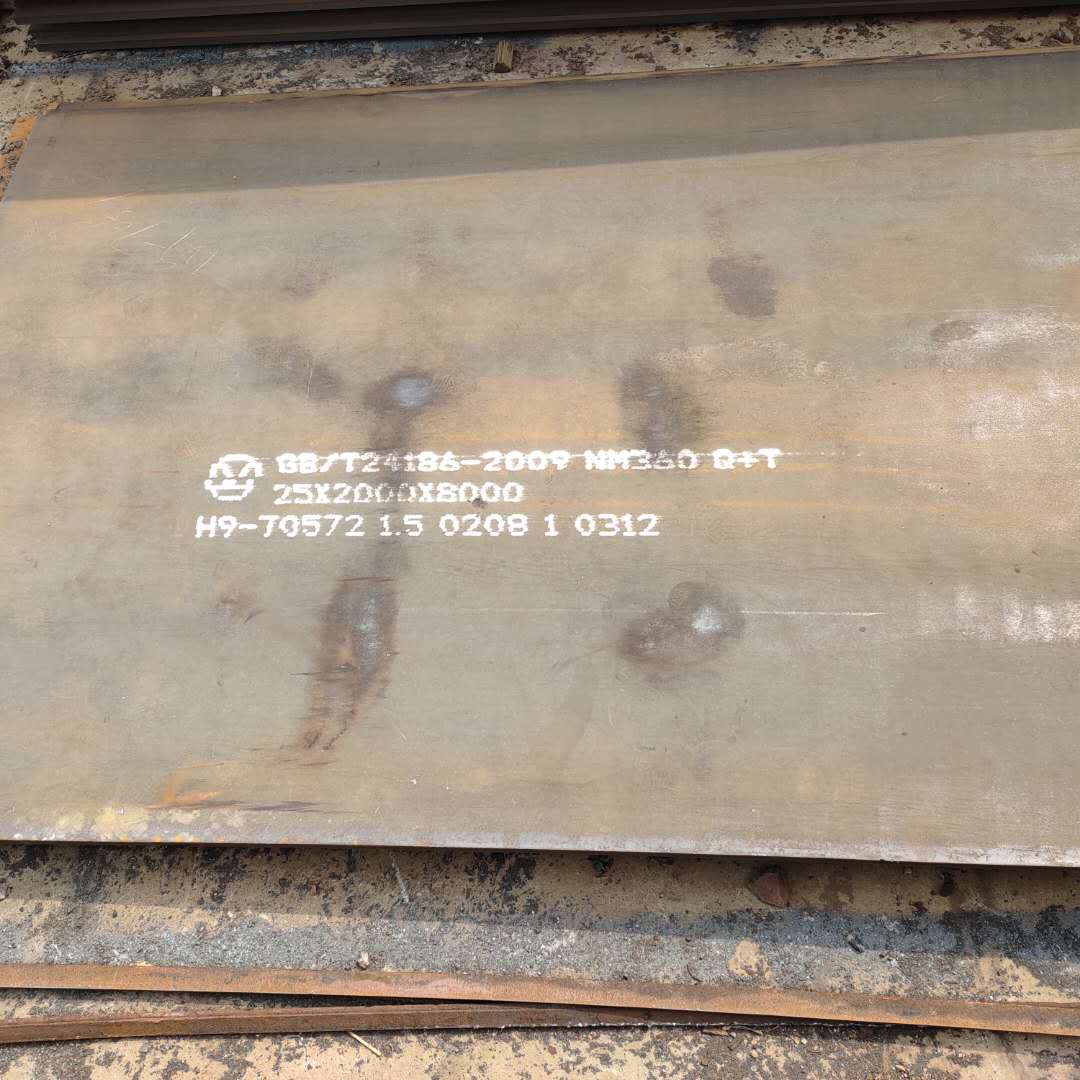

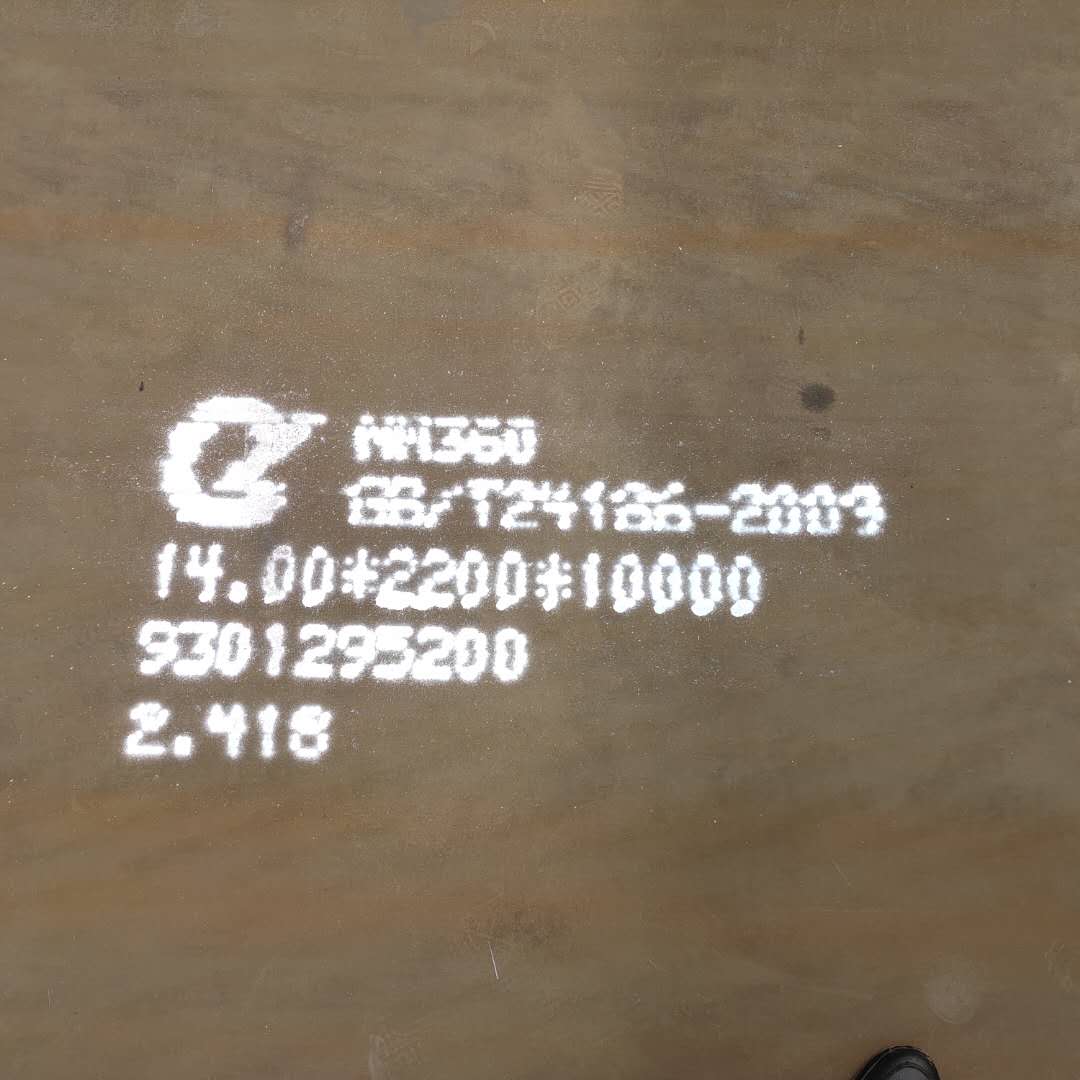

| Umgangatho | IBanga | |

| eTshayina | NM360.NM400.NM450 NM500 | |

| Swiden | HARDOX400,HARDOXX450.HARDOX500.HARDOX600,SB-50,SB-45 | |

| Jemani | XAR400.XAR450.XAR500.XAR600.Dilidur400,illidur500 | |

| Bheljiyam | QUARD400,QUARD450.QUARD500 | |

| Fransi | FORA400, FORA500, Creusabro4800, Creusabro8000 | |

| Japhan | JFE-EH360 JFE-EH400 JFE-EH500 WELHARD400 WEL-HARD500 | |

| I-MN13 Ipleyiti yentsimbi ekwazi ukumelana nokunxitywa kwemanganese ephezulu: Umxholo wemanganese yi-130%, emalunga namaxesha ali-10 entsimbi eqhelekileyo engagugiyo, kwaye ixabiso liphezulu. | ||

| Iinkcukacha zobungakanani (mm) | ||

| Ukutyeba | 3-250mmUbungakanani obuqhelekileyo:8/10/12/14/16/18/20/25/30/40/50/60 | |

| Ububanzi | 1050-2500mmUbungakanani obuqhelekileyo: 2000/2200mm | |

| Ubude | 3000-12000mm | |

| Ubungakanani obuqhelekileyo | 8000/10000/12000 | |

Qaphela: sibonelela ngenkonzo yokwenza ngokwezifiso, yonke ityhubhu yentsimbi iya kuxhomekeka kuyilo lwakho ukuyivelisa.